A pressure tank is designed to hold gases or liquids at a pressure that differs greatly from ambient pressure. Although pressurized tanks are quite dangerous, fatal accidents have occurred throughout the history of their development and operation. Therefore, pressure tank design, production and operation are regulated by engineering authorities supported by legislation.

Pressure tank design includes parameters such as maximum safe working pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for rupture). The pressure tank is tested by non-destructive testing with ultrasonic testing, radiography and pressure tests. Hydrostatic tests use water, but air or another gas is used for pneumatic tests. Hydrostatic testing, a safer method for the pressure tank, is preferred because less energy is released if a leak occurs.

Pressure Tank Features

- Pressure Tank Format

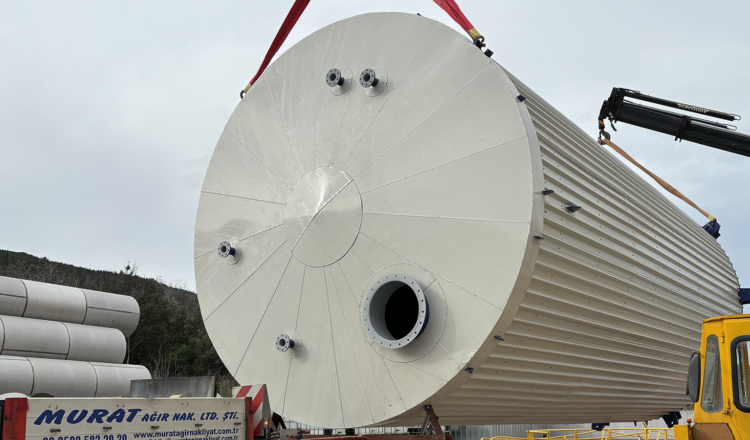

- Pressure tanks can theoretically take almost any shape, but shapes consisting of spheres, cylinders and cones are generally used. It has a cylinder design with end caps, commonly called caps. Head shapes are often hemispherical or torispheric, but more complex shapes are not suitable for safe operation.

- Construction Materials

- Steel was used for the pressure tank, which was manufactured using special methods. To produce a cylindrical or spherical pressure vessel, rolled and forged parts will need to be welded together. If special precautions are not taken during this process, some mechanical properties of the steel obtained by rolling or forging may be negatively affected by welding. In addition to mechanical strength, steel with high impact resistance is used for pressure tank materials, especially those used at low temperatures. In applications where carbon steel corrodes, special corrosion-resistant materials should be used.

- Usage areas

- Pressure tanks are used in a variety of applications in both industry and the private sector. They are used in these sectors as industrial compressed air receivers and hot water storage tanks. Pressure tanks are especially in demand in pressure chambers, distillation towers, pressure reactors, autoclaves and mining operations, oil refineries and petrochemical plants, nuclear reactor boilers, rail vehicle air brake reservoirs, road vehicle air brake reservoirs and many other areas.